Liquid milk processing equipment

Highlight Features of Milk Processing Equipment

MEC Group Co., Ltd. is professional China milk processing equipment suppliers. We founded in 1994, has become one of leading processing manufacturer of advanced equipment and quality packaging for dairy productions. We manufacture, install and commission complete dairy processing lines for treating raw milk and also for filling and packaging milk.

We focus on research and development of new technologies, and have rich experiences in pasteurized milk and UHT milk processing equipment such as milk reception, Cream separation, treatment, milk standardization, liquid milk filling, etc.

We will always supply the full design and possibilities we can offer according to the customer's requirement and budget of milk processing equipment and dairy processing plant.

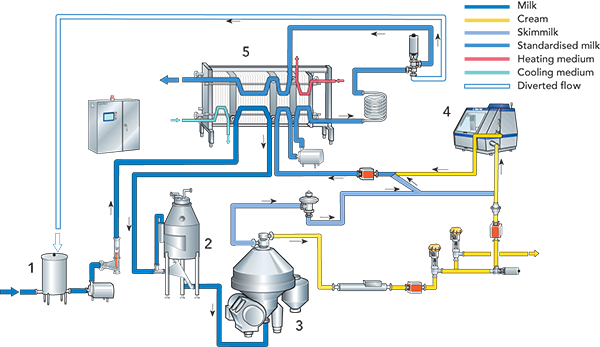

The process of pasteurized milk production

- 1. Balance tank

- 2. Deaerator

- 3. Separator

- 4. Homogenizer

- 5. Plate heat exchanger

Pasteurized milk is also called sterilized milk. It is made of qualified fresh cow milk as raw material. It is purified milk by centrifugation, standardization, homogenization, pasteurization, cooling and filling, and is directly supplied to consumers as commercial milk.

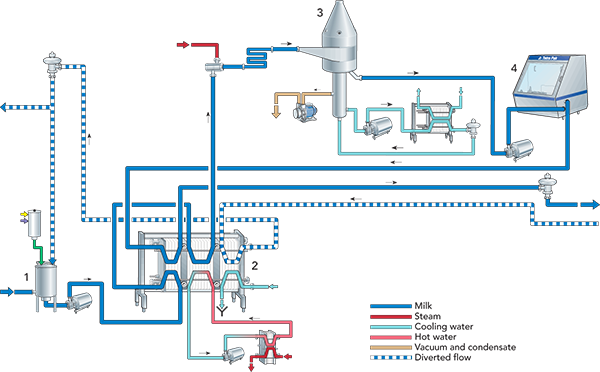

The process of UHT milk production

- 1. Balance tank milk

- 2. Plate heat exchanger

- 3. Steam injection head

- 4. Aseptic homogenizer

In a modern UHT plant, the milk is pumped through a closed system. On the way it is pre-heated, high-heat treated, homogenized, cooled and packed aseptically without any re-infection. The milk is usually treated at 135 – 150°C for a few seconds, by either indirect heating, direct steam injection or steam infusion.

We will provide professional customized solutions for your needs.

Tel:

Tel: WhatsApp:

WhatsApp: