Milk Pouch Filling Machine

Capacity: 4000-7000 pcs/h

Filling volume: 100-500ml

Filling volume adjustment method: step-less adjustment

Filling head number: Double heads

Packaging form: Three side sealing or Back sealing

Total power: 6kw

Compressed air pressure: ≥0.6Mpa

Machine features:

- Full-automatic control system: machine can complete film feed, shape-forming and sealing automatically, and can control each step of the whole system.

- Lower utility consumption: consumption of power, compressed air, and water is lower, which can reduce the cost of customer.

- Advanced pneumatic control system: this pneumatic control system improved the abrasion problem of the machine, which reduces customer’s maintenance work and cost.

- High performance air filter, which guarantee the air cleanness of filling chamber while production, and improve the product aseptic performance greatly.

****************************************************************************

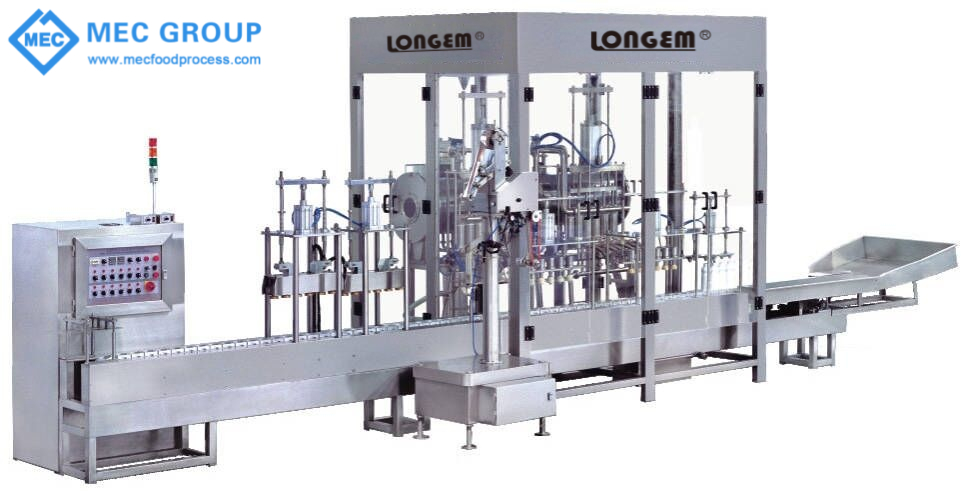

Plastic Bottle Filling and Sealing Machine

Filling Volume: 100-2000ml

Capacity: 2000-11000 Bottles/hour

Main technical features:

- Use Electrical control system approved by CE standard, Electrical box with waterproof groove.

- Use European or American pneumatic components

- Use German Siemens PLC, Japanese Pro-face touch screen, German Rexroth servo motor, French Schneider contactor etc. (Transformer, reducer from famous brands in China)

- Use precise stepper

- Use engineering plastic moldboard

- Use thickening double chain made of stainless steel to lengthen the life of the chain

- Use stainless steel square tube for machine body

- Filling system fixes with Germany membrane valve

- Use ceramic pump and ceramic pulling valve

- Use the technique of floating sealer to ensure the sealing quality

- Fix with seal hopper, machine can be connected to CIP device

- Use low pressure protection technique, preventing machine’s starting in low pressure, increasing machine’s reliability and stability

- Use mechanical jam safety protection device, make sure machine normally running

- Easy clean and maintain

Tel:

Tel: WhatsApp:

WhatsApp: