Butter processing equipment

Highlight Features

We offer a complete turnkey solution or separate machines for the production of cream and butter complying to the customers application.

With advanced production equipments and our own knowhow, the butter production line can continuously and stably produce high-quality butter.

With a team of engineers and skilled technicians, we have designed and produced China's first fully automatic Continuous Butter Making Machine, and will design and support efficient and optimized production lines according to customer needs.

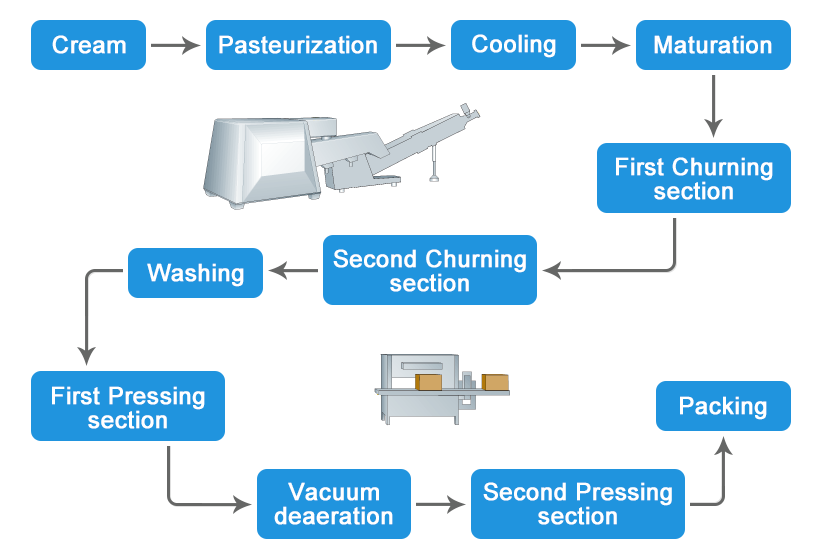

The process of butter production:

We will provide professional customized solutions for your needs.

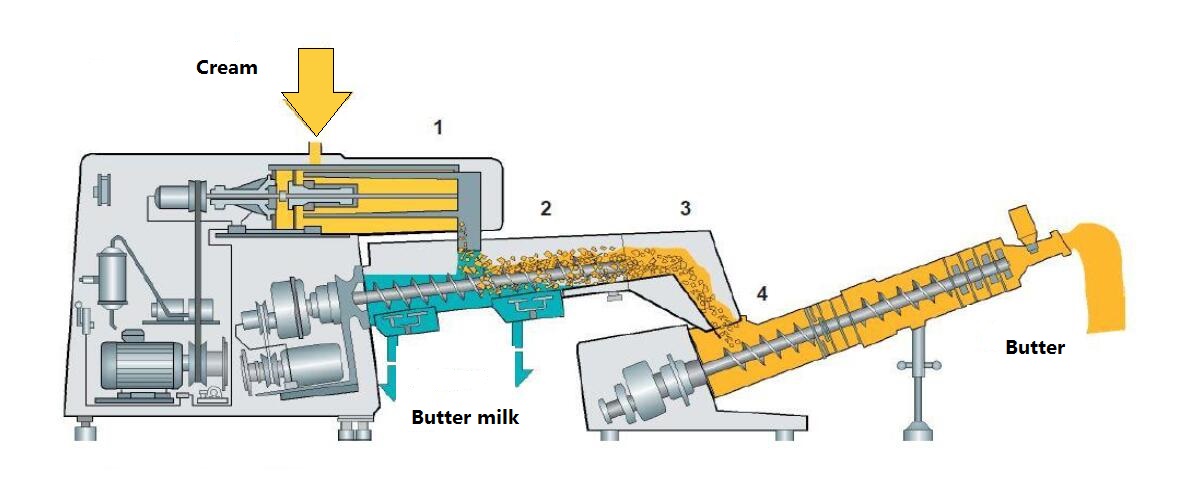

Continuous Butter Making Machine

This equipment is specially used to produce cream products with the fat content of no less than 80%, and the produced cream is stable in grade and good in shape. In addition, the formation of cream, separation of buttermilk, emission of air and cream plasticizing are all finished automatically and continuously in the corresponding parts of the equipment. So this equipment is featured by simple operation, effectiveness and time-saving and high cream yield. Since the production of cream with this equipment is carried out in a closed system, the external pollution risk for the product is extremely low.

This equipment is novel in design and reasonable in structure, and both appearance and performance reach the advanced level in the world, which makes it become the desirable choice for the majority of dairy product enterprises.

|

Application |

Sweet butter, sour butter and salted butter |

||

|

Production capacity |

Min. |

750kg/h |

|

|

Max. |

1500kg/h |

||

|

Optimum cream feeding temperature |

9℃-13℃ |

||

|

Basic moisture of butter |

≈16% |

||

|

Equipment size |

L: 5662mm * W: 1556mm * H:2780mm |

||

|

Gross weight |

≈5000kg |

||

|

Motor Power |

First Churning section |

22kW |

|

|

Second Churning section |

3kW |

||

|

First Pressing section |

5.5kW |

||

|

Second Pressing section |

7.5kW |

||

|

Start-up mode |

Variable frequency control of all motors |

||

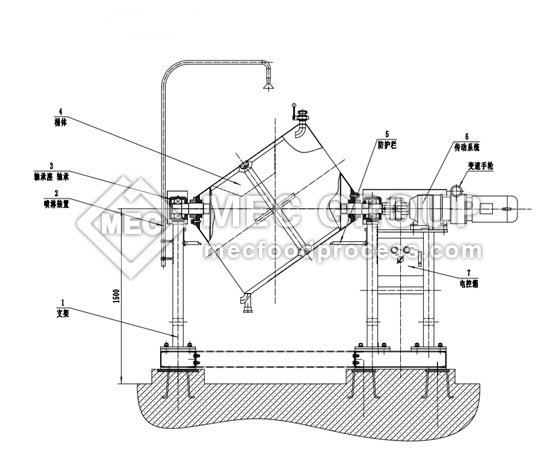

Butter churning machine for batch production

The butter churning machine for batch production is composed of a special-shaped churning barrel, a geared motor with brake, a frame, a support, a safety guardrail, a spray device, etc. There is a retaining rod horizontally in the churning barrel. When the churning barrel rotates, the material will move from the bottom to the top of the barrel. Due to its own weight, the material falls freely and collides with the retaining rod and the barrel wall, the mass of cream will be pulled apart and aggregated from time to time to achieve the effect of butter making and stirring. Generally, the filling amount of cream in the churning barrel is about 50% of its total volume. The rotation speed of the churning barrel should not be too fast or too slow, and the centrifugal force generated on the cream when rotating is slightly less than its own gravity, in order to facilitate the butter making and stirring of the cream.

Butter churning machine (Square barrel type)

|

Main body material |

SUS304 |

|

Production capacity |

≤1000kg/batch |

|

Working temperature |

8~15℃ |

|

Motor power |

3KW |

|

Speed |

9.6-48rpm |

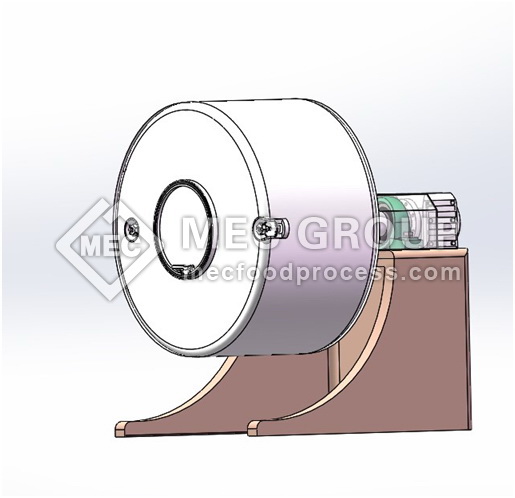

Butter churning machine (Roller type)

|

Main body material |

SUS304 |

|

Production capacity |

≤1000kg/batch |

|

Working temperature |

10~15℃ |

|

Motor power |

11KW |

|

Speed |

15-26rpm |

Accessories

Temperature control unit

It is used to adjust the temperature of the cream so that it is suitable for the feeding temperature of the Continuous Butter Making Machine.

|

Production capacity |

From 1T/h to 3.7T /h |

|

Temperature regulation range |

8-14℃ |

|

Heat exchange area |

2㎡ |

|

CIP temperature |

65-95℃ |

|

Power |

1.5KW |

|

Voltage/frequency |

380V/50Hz |

|

Gross weight |

≈200kg |

|

Equipment size |

2000mm×1000mm×1400mm |

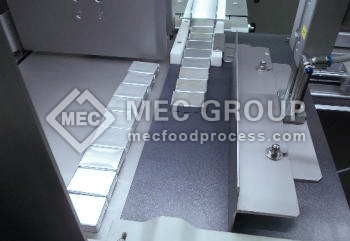

Butter packing machine

This packaging machine specially designed for the packaging of butter, margarine or similar products in cartons (5-30 kg).

|

Total capacity |

3.5Kw |

|

Main shaft speed |

30r/min |

|

Cross-sectional area of extrusion screw |

≈(100×2) mm2 |

|

Gas consumption |

100L/min |

|

Cooling area |

≈ 2m2 |

|

Ice water consumption |

≈ 0.5m3 |

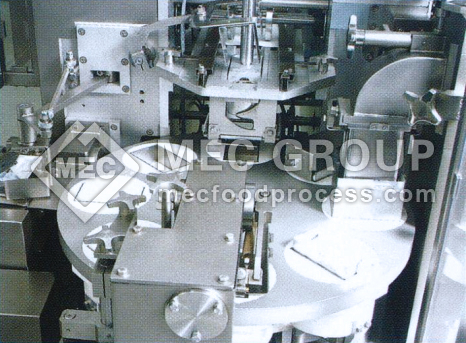

Butter small packaging machine with aluminum foil

This small packaging machine specially designed for small packages of butter with aluminum foil. According to the needs of customers, we can design and customize 10g/15g/25g aluminum foil small packaging and 50-800g large aluminum foil packaging equipment.

Tel:

Tel: WhatsApp:

WhatsApp: